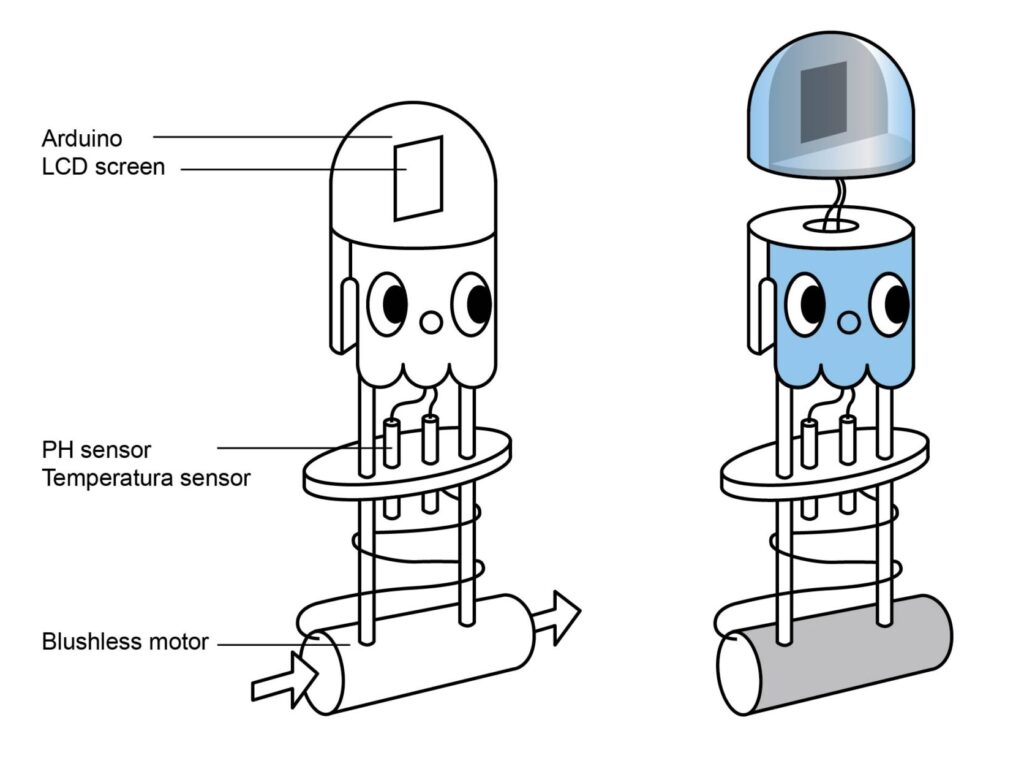

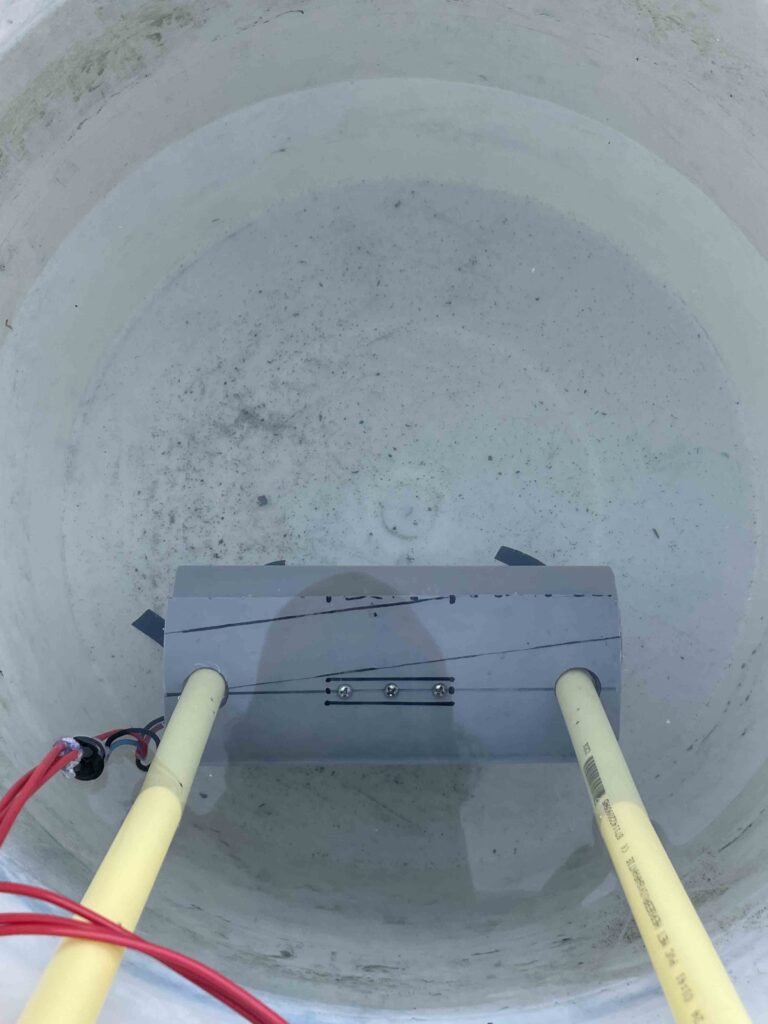

AIP is a compact sensor system that automates the management of indigo dye vats.

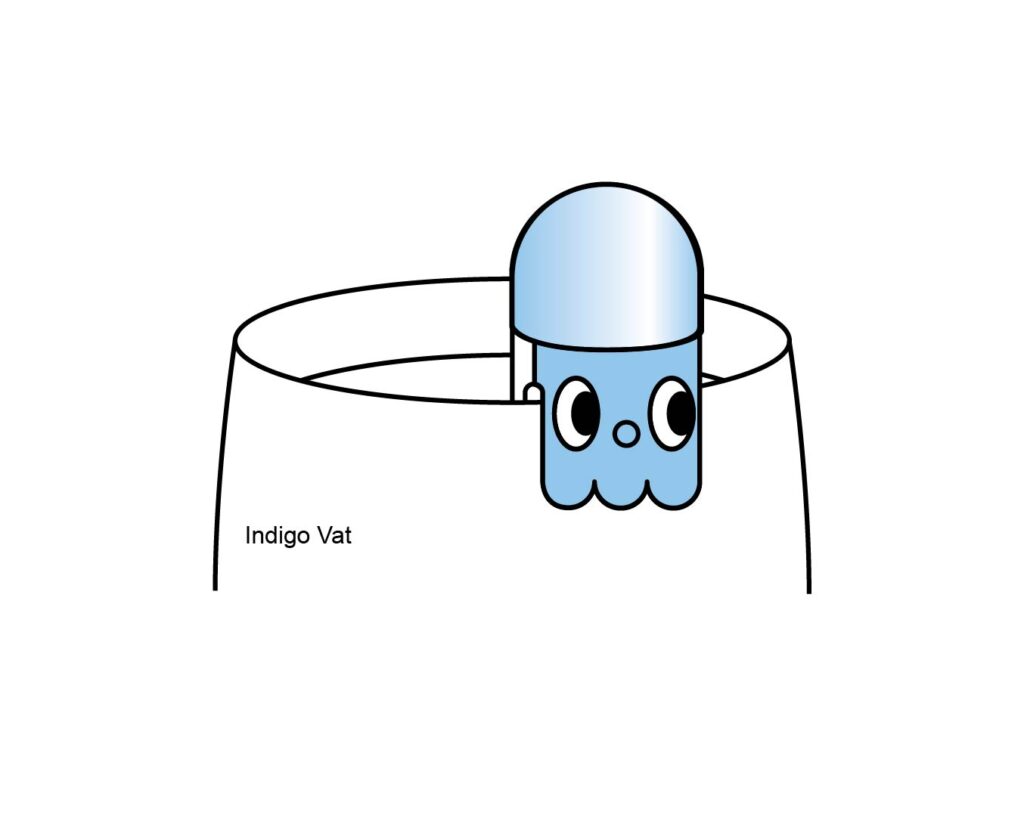

It attaches to the rim of the vat and can be retrofitted onto existing indigo vats.

Key Components:

- Temperature sensor

- pH sensor

- ORP sensor

- LCD screen

- Brushless motor for stirring

- 12V battery

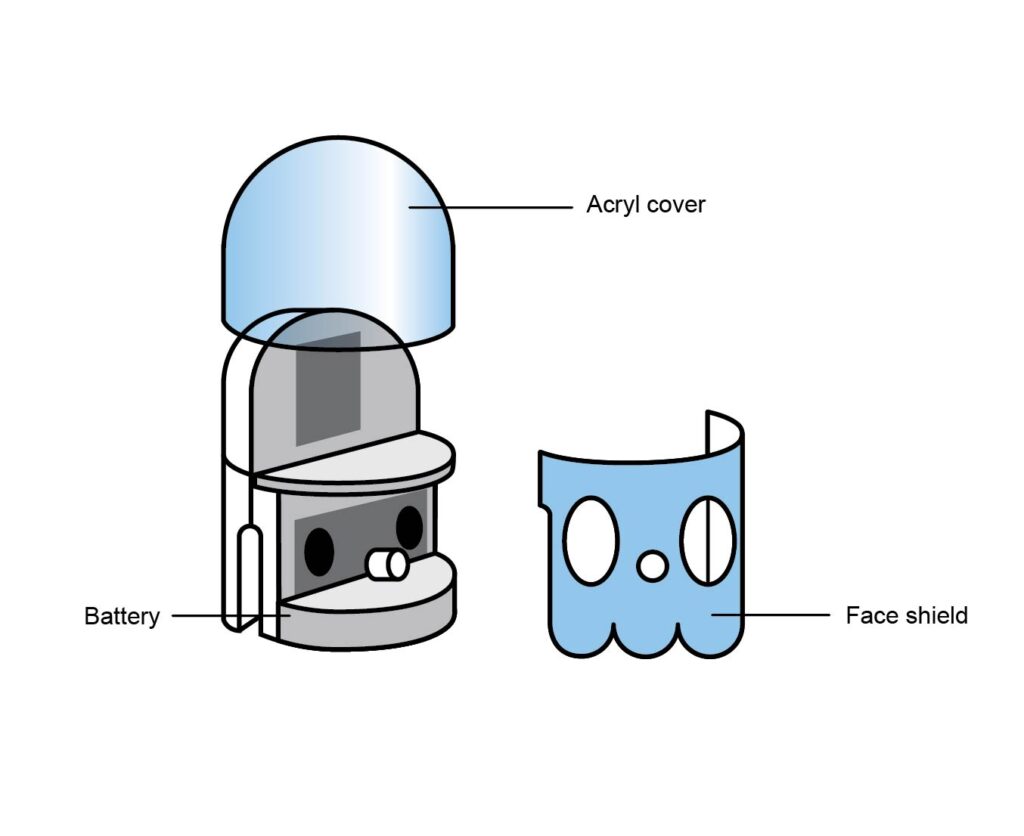

The system can be disassembled for easy maintenance.

It can be installed on the edge of an existing vat, allowing continued use of the current vat. Another benefit is the reduced initial investment.

Automatic Liquid Mixer experiment

This mixer is equipped with a motor and fan blade. The time and power can be set, allowing it to automatically mix the indigo liquid.

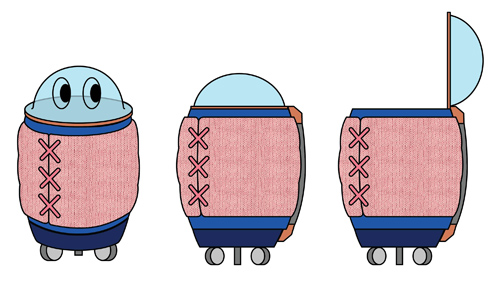

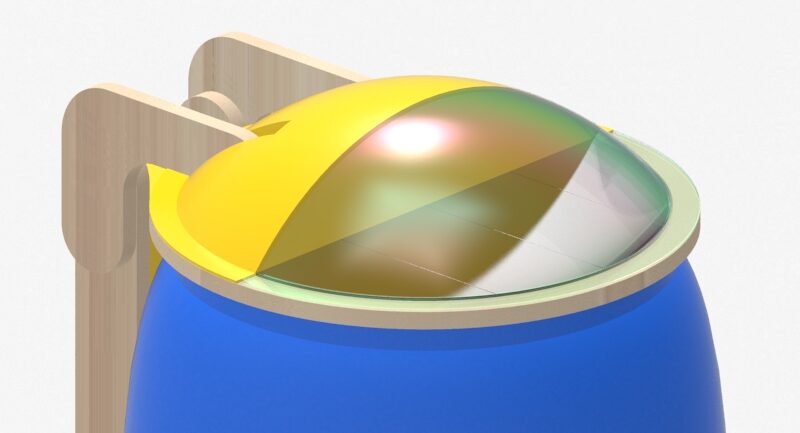

Mr.TINO / Sig.TINO

The Indigo Sensor, developed from the AIP, transforms the indigo fermentation vat itself into a sensor. Managing indigo dyeing requires stable temperature control, and with its wheeled design, Tino can be freely moved to seek optimal temperatures. Additionally, it can autonomously perform stirring, pH adjustment, and reduction concentration measurements, significantly reducing the labor required for traditional indigo vat management.

“Tino” is Italian for “barrel,” and containers like wine barrels and indigo vats are also referred to as il tino. It is also commonly used as a surname in Italy.

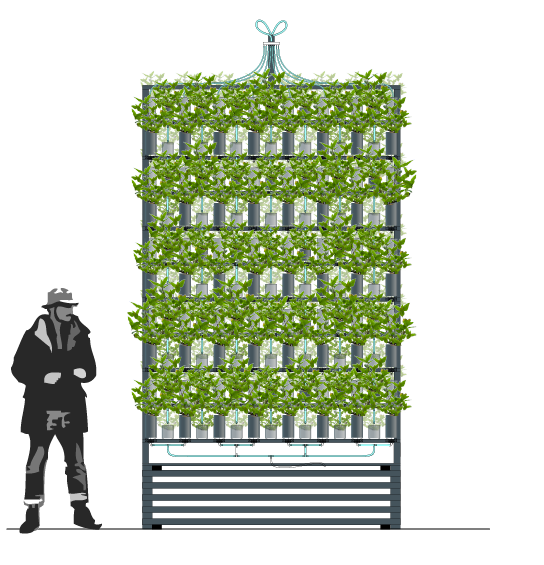

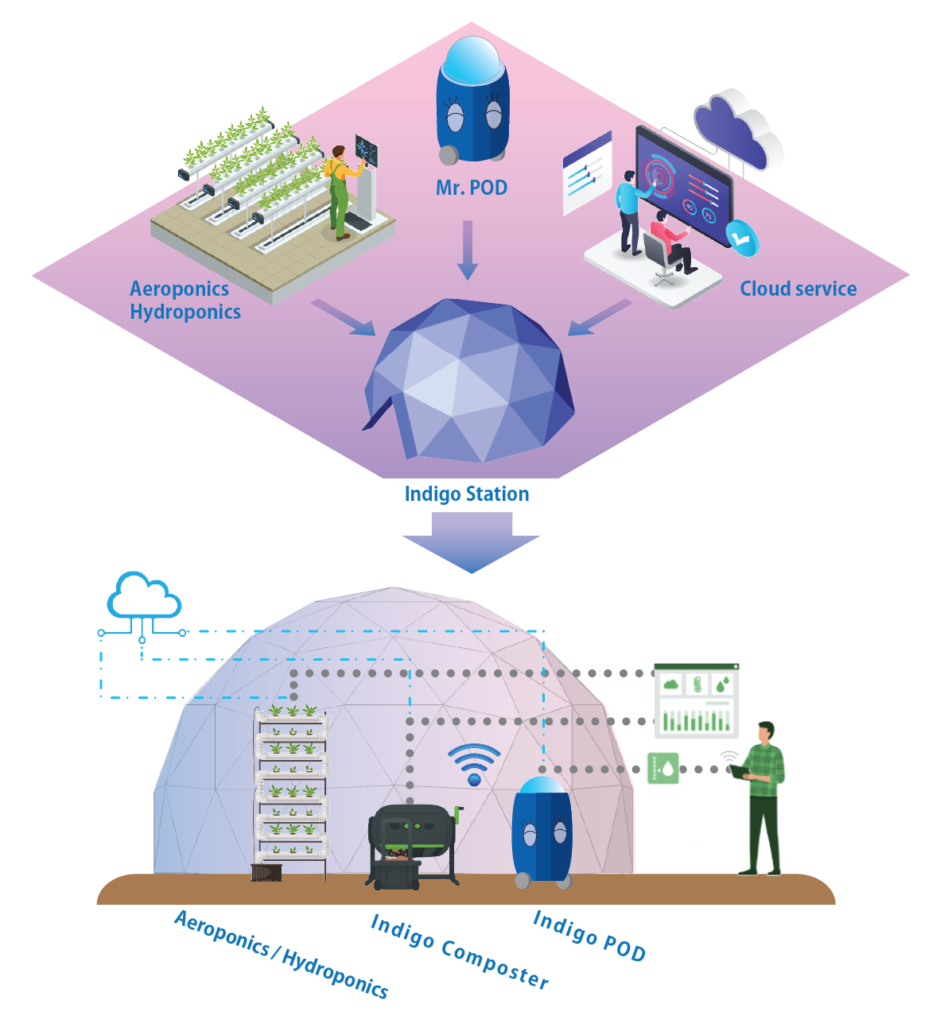

Indigo Station

The Indigo Station consists of a cultivation area, dyeing area, and compost area, all managed by an IoT-controlled system. This station serves as an open space for artists, hobbyists, and dyers to explore indigo dyeing.

Read more: AIP / Automatic Indigo Pod