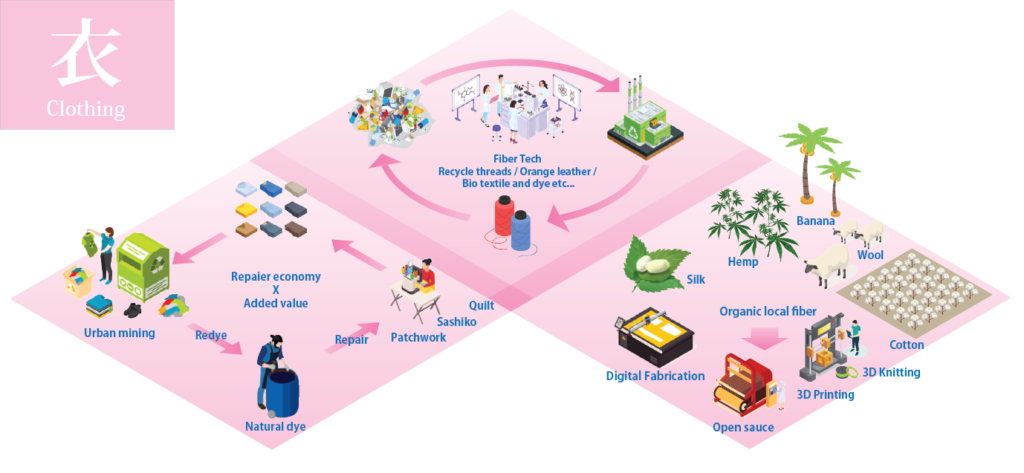

In the post-fast fashion world, these three types of manufacturing will remain: using new fiber, using local fibers, and using fabrics that already exist.

This is the matrix of textile production.

Using New Fibers:

In the field of mass production, the use of new technological fibers is expected. Examples include recycled fibers from plastic or used garments, mushroom leather, or bio-textiles.

Using Local Fibers:

Utilizing local materials, such as banana fiber, wool, cotton, silk, etc., is considered. However, this method has limitations for mass production, so it is typically reserved for local consumption.

Using Fabrics That Already Exist:

Opting for existing fabrics to create our garments is another viable choice. Given the abundance of fabrics and garments produced until now, we can repurpose these materials by repairing or customizing them ourselves. For our customization efforts, we will apply natural indigo dyeing techniques.

This matrix will serve as our production framework

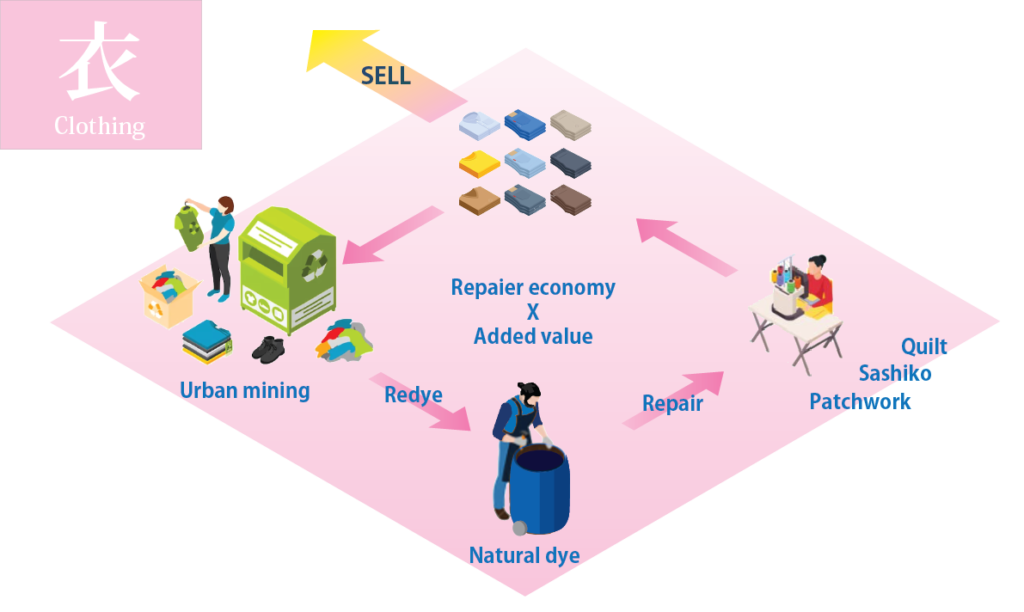

We are working towards creating a repair economy system designed to extend the lifespan of our garments through repairs and re-dyeing, ensuring they can be used for several generations. This approach not only promotes sustainability but also adds value to our products through modifications and customization.

The more you customize, the greater the value you imbue in your garments!

Of course, the success of this endeavor will rely on the talents of designers and artists who will be essential for these productions.

Various techniques, such as Sashiko (a Japanese patchwork technique), quilting, and other repair methods, are likely to play a significant role in this project.

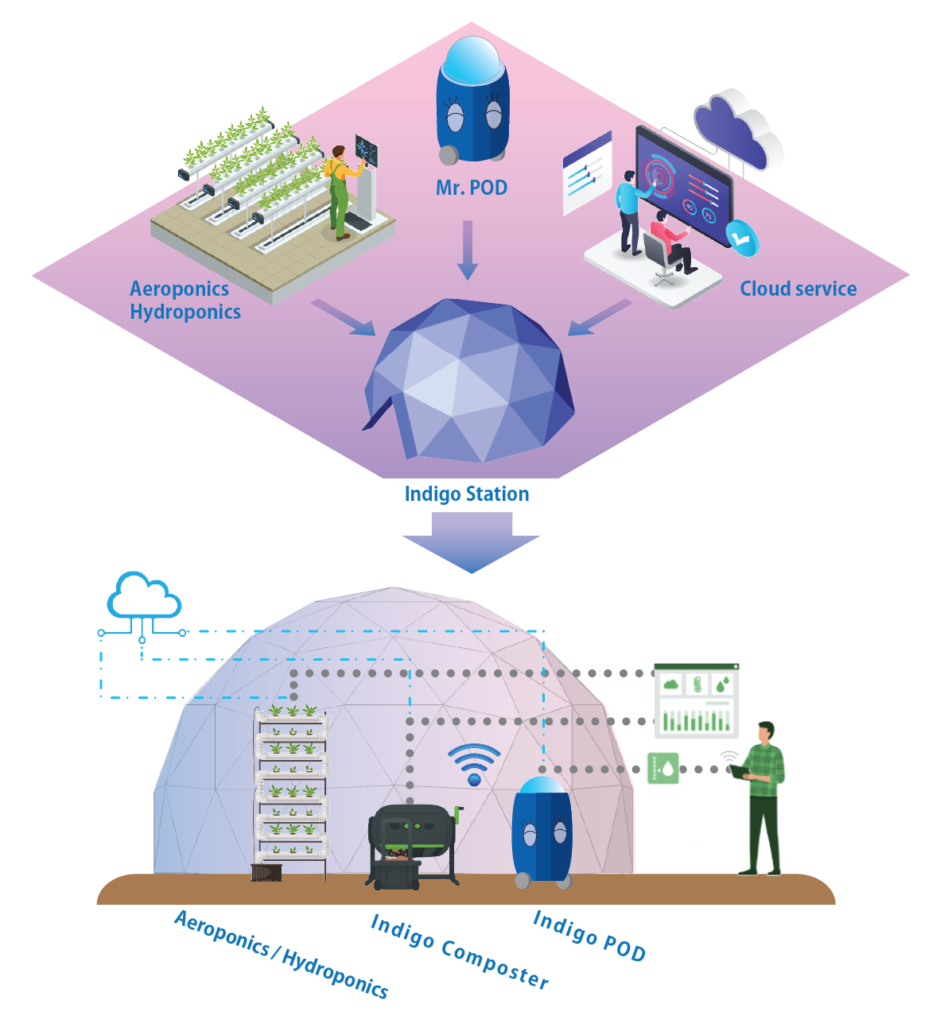

Mr. Pod / Indigo pod project

This is our proposal for indigo production.

Why indigo?

We believe that Japanese indigo, Persicaria Tinctoria, is an ideal fit for this project due to its unique characteristics. Japanese indigo is easy to cultivate under various conditions, making it suitable for large-scale production. Unlike other indigo-containing plants, it can be grown using hydroponics or aeroponics and is less sensitive to climatic conditions.

Indigo Station

For the production of indigo, we propose an Indigo Station equipped with all the necessary facilities for indigo cultivation and production. At each station, we will install an ‘Indigo Pod,’ a container filled with indigo dye. You can visit and use it to dye your fabrics whenever you want.

Indigo can be grown either hydroponically or in a controlled environment such as a greenhouse, where temperature and humidity can be precisely regulated. This method allows for vertical planting, requires minimal space, and enables year-round harvesting with reduced labor demands. In contrast, Japanese indigo farmers spend the entire summer on their harvests.

Mr.POD /Sensor controlled indigo container

We are also introducing ‘Mr. Indigo,’ a sensorized indigo container designed for preparing indigo color using fermentation methods. The preparation of indigo color can be achieved through various methods. We plan to employ traditional Japanese indigo preparation techniques, such as the fermentation method known as ‘Sukumo Vat.’ This method relies on the power of bacteria to create indigo color and doesn’t require the use of chemical components like hydrosulphite, iron sulfate, or fructose.

The color produced using this method will have a longer lifespan, exceeding one year, compared to just one month when chemical components are used. This extended durability is attributed to the continuous growth of bacteria within the pod, allowing for ongoing reduction over an extended period.

“SUKUMO” Indigo composter

To apply the SUKUMO method, indigo leaves need to undergo fermentation similar to a ripened composting process. For this purpose, we plan to utilize an electric home composter, which makes the production process more efficient and accessible compared to the traditional Japanese method.

All instruments will be cloud-connected and remotely controlled and monitored.

It is crucial for the future of creation that individuals involved in production collaborate to establish a system where raw materials and energy circulate harmoniously. This concept is also a central focus in “Valley of the Wind” .

Our project aims to bring about a future characterized by a thriving, humane coexistence with nature.

Who will benefit and find greater happiness from this initiative?

- This project will bring positive changes to farmers and artisans, especially those facing challenges with succession. It will enhance their efficiency, granting them more time which can be dedicated to promotion or creative endeavors.

- Firstly, the reduced cost of indigo dyeing will boost the sales of farmers and artisans.

- Secondly, indigo dyeing will become more accessible to the public and could evolve into a local business, akin to dry-cleaning or a shoe repair shop.

Importantly, this doesn’t imply that such services will replace the work of existing artisans. - This initiative could mark the beginning of a shift towards a longer-lasting lifestyle. Furthermore, introducing these practices to developing countries, like those in Africa, could contribute to a reduction in environmental impac.

Why is this an issue now?

- We currently face two choices: fast fashion or high fashion. However, the issue at hand is the absence of a third option.

- This third option doesn’t pertain to a price range between fast fashion and high fashion. It revolves around establishing a system that enables us to obtain what we require precisely when we require it and in the quantities we need.

Why have we not been able to achieve this before?

- This hasn’t been feasible in the past due to the absence of advanced sensing technology and cloud services.

- As our lifestyles evolved, the demand for traditional arts and crafts declined. Consequently, these valuable traditional skills became protected, and we missed the opportunity to integrate them into modern life.

What is the inspiration for this idea?

- In Japan, during the Edo period (1603-1868), people embraced a sustainable lifestyle that holds valuable lessons for us today. Among these lessons is the art of indigo dyeing.

When their clothing became damaged or faded, they would refresh it by re-dyeing it with indigo. If holes appeared, they would skillfully mend them using the Sashiko technique. When garments were beyond repair, they would repurpose them as strips for crafting children’s clothing, and eventually, as floor cloths - Why not take a cue from Dutch agriculture and embrace methods that leverage technology to enhance production efficiency while reducing the need for extensive manpower?